自动上料机+焊缝检测

Auto feeding unit/welding seam detection

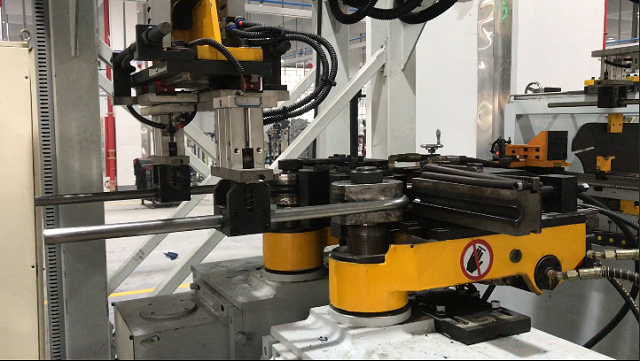

桁架机械臂给自动伺服双弯机上料

Truss Arm feeds tube to servo bender

桁架机械臂给双弯机下料

Truss Arm unload from the double bender

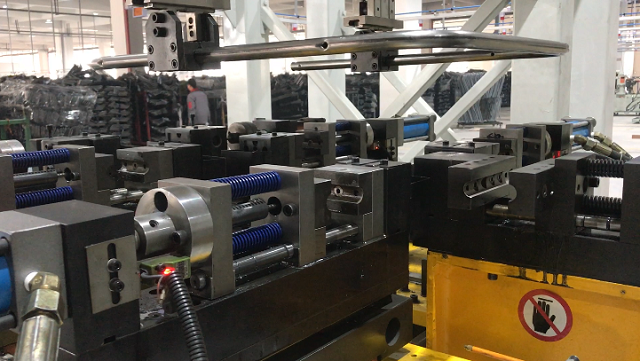

可调节孔位自动冲孔机

Punching Set with adjustable hole position

完成冲孔卸载

Complete punching unloading

卸载产品管件到料架

Unload the product pipe to the rack

完成的管件 Finished product

U形管弯管机自动生产线主要特点:

1)节省人工显著,全线只需要一个人工给自动生产线整捆批量上料,其它时间可以干其它事情

2)生产节拍快,效率高,操作简单

3)适合管件范围:800-2000mm管径范围:12-38mm

4)冲孔孔位在设计范围内可调(可以非标定制尺寸)

5)伺服电机控制双头弯管机,精度高,没有液压系统温度变化之误差

6)数字屏幕操作,可保存至少50种加工参数

Main features of U-tube automatic production line:

1) Significant labor saving, the whole line only needs one person to load the automatic production line in batches, and other things can be done at other times

2) Fast production cycle, high efficiency and simple operation

3) Suitable pipe fitting range: 800-2000mm pipe diameter range: 12-38mm

4) The punching hole position can be adjusted within the design range (non-standard customized size)

5) The servo motor controls the elbows with high precision and no error of temperature changes in the hydraulic system

6) Digital screen operation, can save at least 50 kinds of processing parameters

为了更好地满足您的需求,请指明您的业务领域、原材料的种类以及其它有助于我们优化方案的信息。